Sharp-point screws are similar to machine screws, but the thread on the screw is a special thread for self-tapping screws. It is used to fasten two thin metal components together to make a single piece, and small holes need to be made in advance in the components. Because of the high hardness of this screw, it can be screwed directly into the hole of the component, forming a responsive internal thread in the component. This type of connection formation is also a removable connection.

The first part of the preparation process, or production process, for the spike-tailed screw is the coiling process. The process is the original coils purchased by the raw material manufacturer. The main parameters of a coil include: A, brand B, name C, specification D, material E, furnace number or batch number F, quantity or weight. The main chemical composition of carbon steel coils are: C, Mn, P, S, Si, Cu, Al, of which the lower the content of Cu, Al, the better.

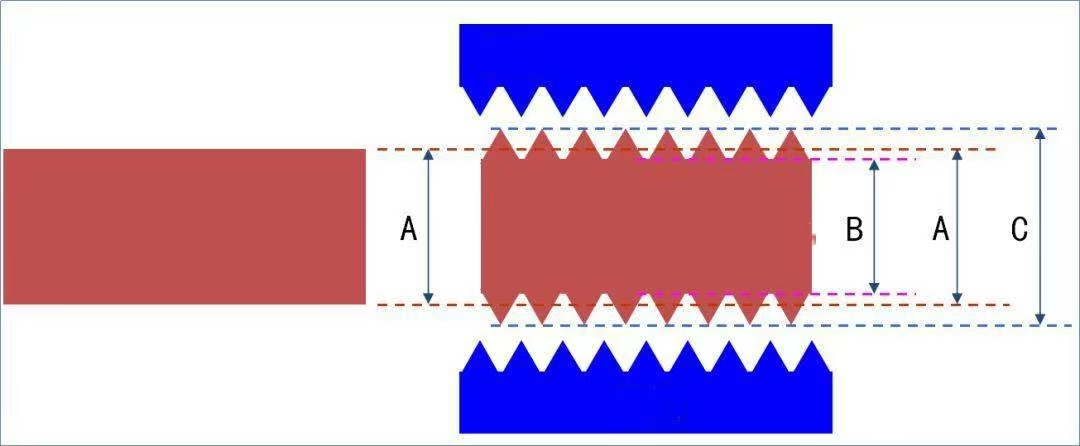

The second process in the production of screws is the wire drawing process. The purpose of the wire drawing process is to achieve the wire diameter we need (e.g. up to 3.5 mm wire drawing).

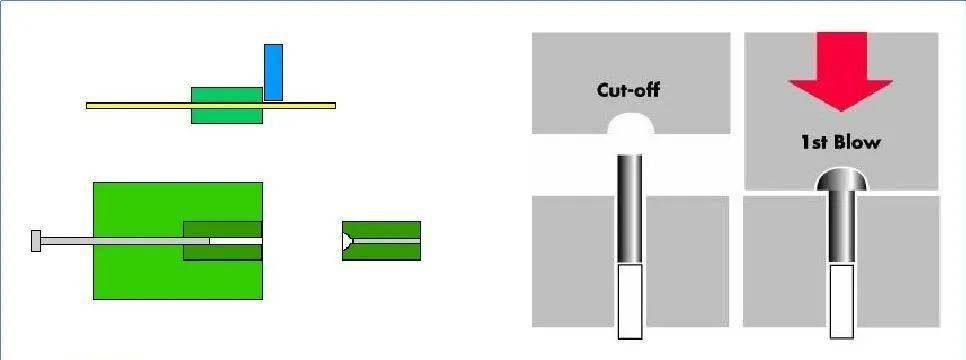

The third process is the cold heading (heading) process. Through the interaction between the dies to shape, first cut the wire, upsetting into screw blanks, forming the head, cross groove (or other head type) thread blank diameter and rod length, rounding under the head, etc.

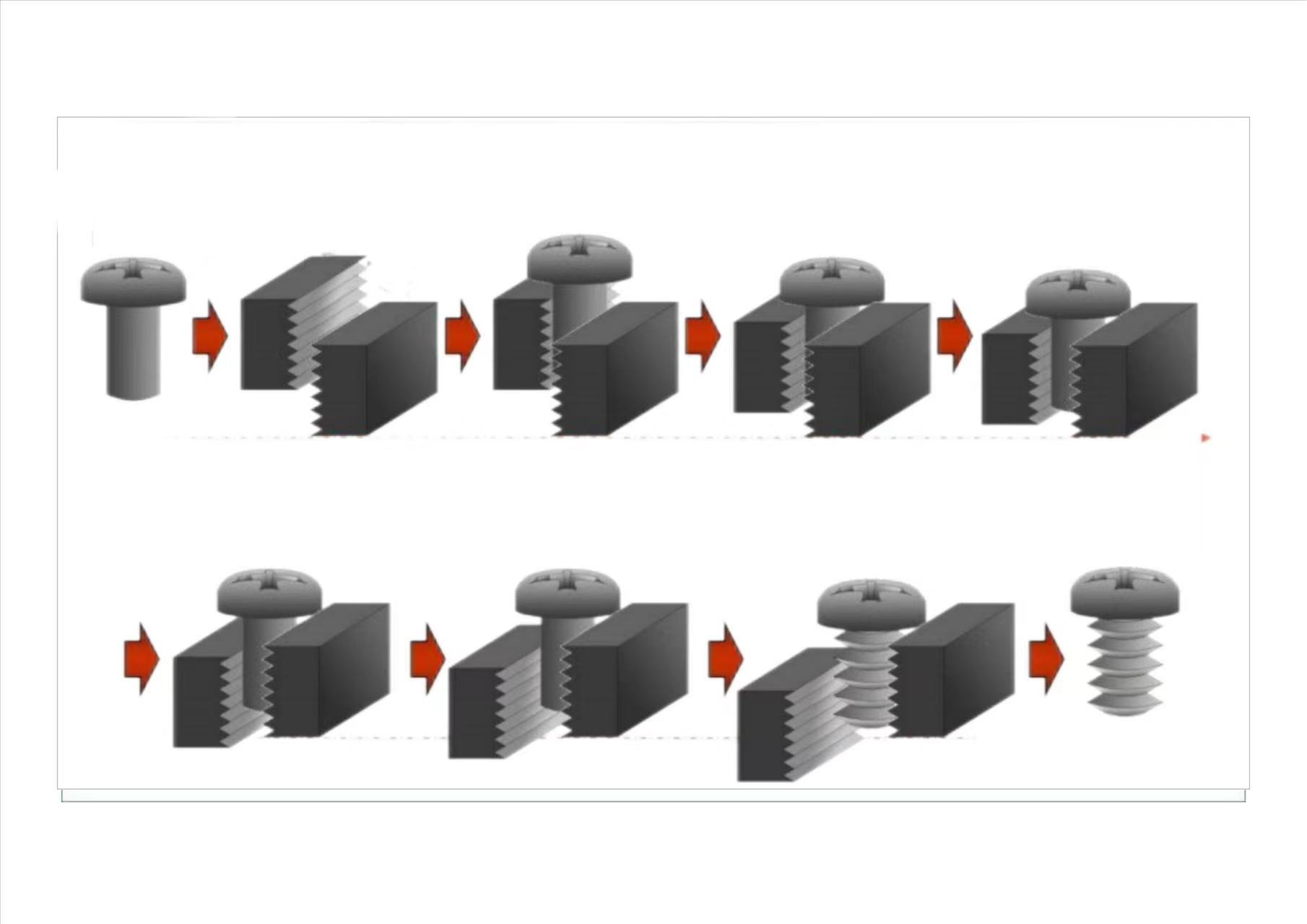

The thread rolling process is the fourth process of production. The threads are rolled out from the cold heading blanks, and the thread pattern is formed by the interaction of the movable and fixed tooth plates.

5、Heat treatment process

01. Purpose:

To make the screw in the cold heading process to get higher hardness and strength

02. Role:

To achieve self-tapping locking of the metal

Improve the mechanical properties of metal parts, such as torsion, tensile, wear resistance

03. Classification:

A. Annealing: (700 ℃ x 4hr): elongated organization - orthogonal polygonization.

B. Carburizing heat treatment (adding carbon to metal parts to improve their surface hardness, for metal materials with low carbon content)

C. Tempering heat treatment (no elements are added to the metal, the internal structure of the metal is changed by the change of temperature to get better mechanical properties)For the Australian market, we have strong confidence, excellent foreign trade salesmen, a variety of products, as a factory, strict control of product delivery and quality, a tacit team, etc., these are the reasons we compete for the Australian market chips.

The final process is the surface treatment process, also known as plating. After plating, the surface of the product can show the desired color effect and surface anti-oxidation plating effect.

XINRUIFENG Fastener's main products are sharp-point screws and drill-point screws.

The sharp-point screw includes drywall screws, chipboard screws, self tapping screws, kinds of csk head, hex head, truss head, pan head, and pan framing head sharp-point screws.

The drill-point screw includes drywall screws drill point, csk head self drilling screws, hex head self drilling screws, hex head with self drilling screws with EPDM; PVC; or rubber washer, truss head self drilling screws, pan head self drilling screws and pan framing self drilling screws.

Excellent quality, competitive price, and timely delivery are the three pillars of our success. And We wish to establish a long-term partnership and reach a win-win with all our clients.

Post time: Jun-28-2023