Fixed Competitive Price Short Drywall Screws - Black Phosphated Bugle Head DIN7505 Drywall Screw – Xinruifeng

Fixed Competitive Price Short Drywall Screws - Black Phosphated Bugle Head DIN7505 Drywall Screw – Xinruifeng Detail:

1. The Drywall Screw is characterized by a bugle head that features a flat top and a concave under-head bearing surface. For this reason, the Drywall Screw is also called Bugle Head Screw. This unique design enables the distribution of the bearing stress over a much wider area than is with a flat head screw.

2. The bugle head offers many benefits which are the followings:

● The bugle head screw has a smoother transition between the shank and the head, which avoids the material to get caught, resulting in a more attractive finish.

● The bugle head can depress sufficiently the surface of wood material without breaking it, which minimizes the risk of damage to the finished product.

● Like the countersunk head, the bugle head also makes the drywall screw lie flush in the material, which makes it a versatile fastener in numerous construction tasks.

Tianjin Xinruifeng Technology Co., Ltd. has been in the fastener industry for nearly 20 years and we can customize all kinds of products per your requirements. We have an established management system and quality control procedure. Excellent quality, competitive price, and timely delivery are the pillars of the company’s foundation. Win-win and long-term cooperation is our final goals when dealing with different clients.

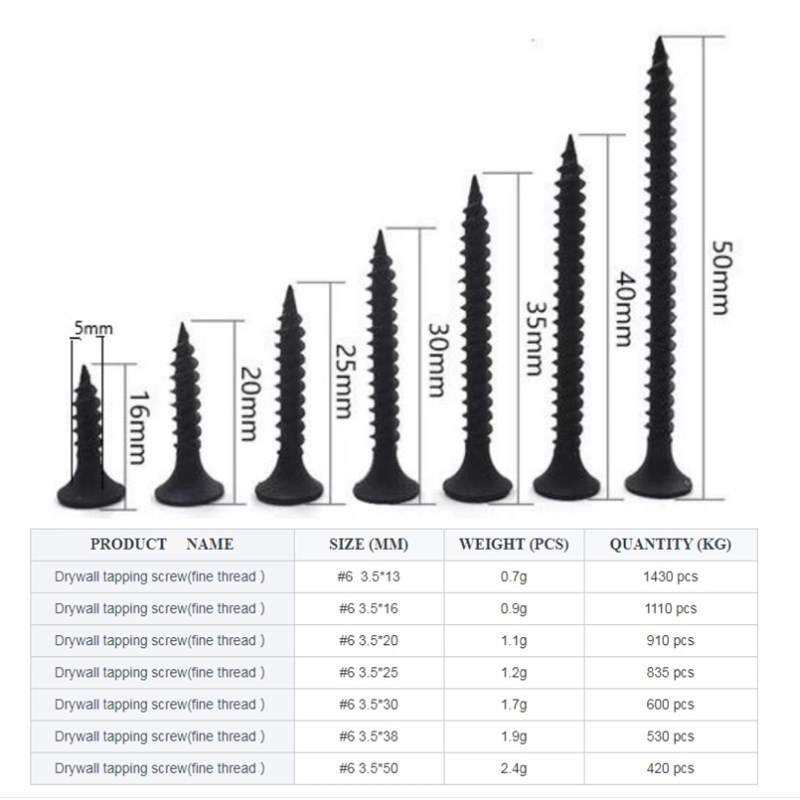

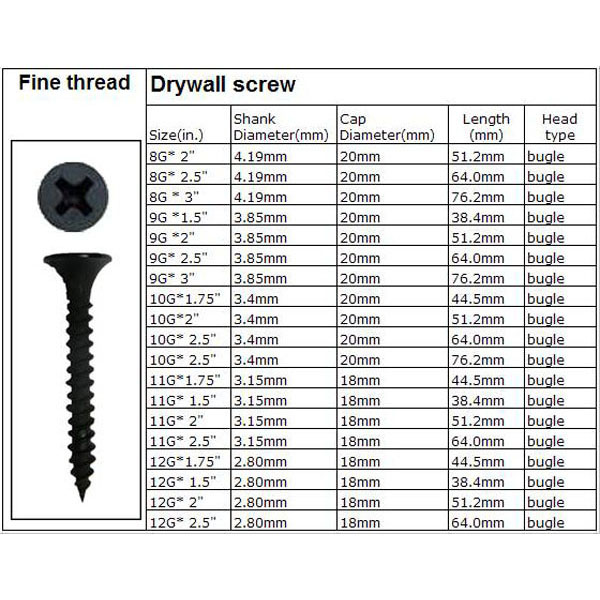

| Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) | Size(mm) | Size(inch) |

| 3.5*13 | #6*1/2 | 3.5*65 | #6*2-1/2 | 4.2*13 | #8*1/2 | 4.2*102 | #8*4 |

| 3.5*16 | #6*5/8 | 3.5*75 | #6*3 | 4.2*16 | #8*5/8 | 4.8*51 | #10*2 |

| 3.5*19 | #6*3/4 | 3.9*20 | #7*3/4 | 4.2*19 | #8*3/4 | 4.8*65 | #10*2-1/2 |

| 3.5*25 | #6*1 | 3.9*25 | #7*1 | 4.2*25 | #8*1 | 4.8*70 | #10*2-3/4 |

| 3.5*29 | #6*1-1/8 | 3.9*30 | #7*1-1/8 | 4.2*32 | #8*1-1/4 | 4.8*75 | #10*3 |

| 3.5*32 | #6*1-1/4 | 3.9*32 | #7*1-1/4 | 4.2*34 | #8*1-1/2 | 4.8*90 | #10*3-1/2 |

| 3.5*35 | #6*1-3/8 | 3.9*35 | #7*1-1/2 | 4.2*38 | #8*1-5/8 | 4.8*100 | #10*4 |

| 3.5*38 | #6*1-1/2 | 3.9*38 | #7*1-5/8 | 4.2*40 | #8*1-3/4 | 4.8*115 | #10*4-1/2 |

| 3.5*41 | #6*1-5/8 | 3.9*40 | #7*1-3/4 | 4.2*51 | #8*2 | 4.8*120 | #10*4-3/4 |

| 3.5*45 | #6*1-3/4 | 3.9*45 | #7*1-7/8 | 4.2*65 | #8*2-1/2 | 4.8*125 | #10*5 |

| 3.5*51 | #6*2 | 3.9*51 | #7*2 | 4.2*70 | #8*2-3/4 | 4.8*127 | #10*5-1/8 |

| 3.5*55 | #6*2-1/8 | 3.9*55 | #7*2-1/8 | 4.2*75 | #8*3 | 4.8*150 | #10*6 |

| 3.5*57 | #6*2-1/4 | 3.9*65 | #7*2-1/2 | 4.2*90 | #8*3-1/2 | 4.8*152 | #10*6-1/8 |

Drywall screw:

1.Heat treatment: It is a method of heating steel to different temperatures and then using different cooling methods to achieve different purposes of changing the properties of steel. The commonly used heat treatments are: quenching, annealing, and tempering. What kind of effects will these three methods produce?

2.Quenching: A heat treatment method in which the steel is heated to above 942 degrees Celsius to make the steel crystals in austenitic state, and then immersed in cold water or cooling oil to quench to make the steel crystals in a martensitic state. This method can increase the strength and hardness of the steel. There is a very big difference in the strength and hardness of the steel with the same label after quenching and without quenching.

3.Annealing: A heat treatment method in which the steel is also heated to an austenitic state and then naturally cooled in air. This method can reduce the strength and hardness of the steel, improve its flexibility, and facilitate processing. Generally, steel will go through this step before processing.

4.Tempering: Whether it is quenched, annealed or press-formed, steel will generate internal stress, and the imbalance of internal stress will affect the structure and mechanical properties of the steel from the inside, so a tempering process is required. The material is kept warm continuously at a temperature of more than 700 degrees, its internal stress is changed and then cooled naturally.

In 2008, Tianjin Xinruifeng Technology Co., Ltd. was established in the beautiful coastal city of Tianjin. After more than a decade’s development, now we are a leading, professional and premium manufacturer with excellent capabilities of design, development, production and export. Our main products include drywall screws, chipboard screws, self-drilling screws and self-tapping screws, which are produced in 3 different production bases with a total area of 16,000 square meters.

We have 280 sets of automatic production equipments, including wire drawing machines, cold-heading machines, thread rolling machines, tailing machines and heat-treatment lines. There are more than 100 staff in our company. Among them, there is an experienced and professional R&D team, who follow an established management system and quality control procedure, allowing us to customize the products according to your specific designs/requirements to the highest quality. Further, we have CE Certification for drywall screws and SGS will conduct audit to our factory on a regular basis. Because of this and our great attention to high quality, there is not a single complaint about quality in the last 5 years.

1. To satisfy the demands from markets and customers, we have more than 300 machines in two shift production in order to provide all kinds of fasteners in the market home and abroad.

2. To prevent any mistakes from happening during the developement, the development procedure is strictly controlled under ISO 9001. From design → information collection → setting developing items → design input → design output → pilot run → design verification → mass production, every stage is strictly inspected & controlled by our R&D team. Based on the precise control from research, drawing, pilot run management and design change, the development will be cost effective and efficient.

Drywall screw series is one of the most important categories in the entire fastener product line. This product is mainly used for the installation of various gypsum boards, lightweight partition walls and ceiling series.

Woven bag, carton, color box+ color carton, pallet etc (per customer’s request).

Generally, the production will take 4-5 weeks for one container. Please check details with us when you have a specific quantity. As a factory, we can guarantee the timely delivery of your order and will try out best to meet your tight deadline. Normally, the shipments will depart from Tianjin Port.

Bugle head drywall screw allows you to make the attachment point even, without protrusions, which is important if this is required by technology or the designer’s idea. The bugle head is recessed into the attached material, drywall, by 1 mm and has a cross-shaped slot PH (Phillips), one of the most common in construction. Screwing can be done as a screwdriver, and for efficiency – with a screwdriver.

However, you need to have a certain skill when using a power tool. The standard sheet has dimensions of 2500x1200x12.5 mm. For ceiling structures, a lightweight analog with a thickness of 9 mm is used; for arched – 6 mm.

The most popular, and hence the best-selling, size of the drywall screw is a fastener 25 mm long – a universal length to fit the attached sheet and firmly entrenched in a metal base.

Long drywall screws are a rare product and are in demand when, for example, it is necessary to additionally fix the structure to a surface that is some distance from the main working one.

The sharp tip of gypsum drywall screw is a design feature that makes the drywall screw in fixing drywall to a metal frame. The tip of the product produces the same self-tapping action, which greatly simplifies the fastening process.

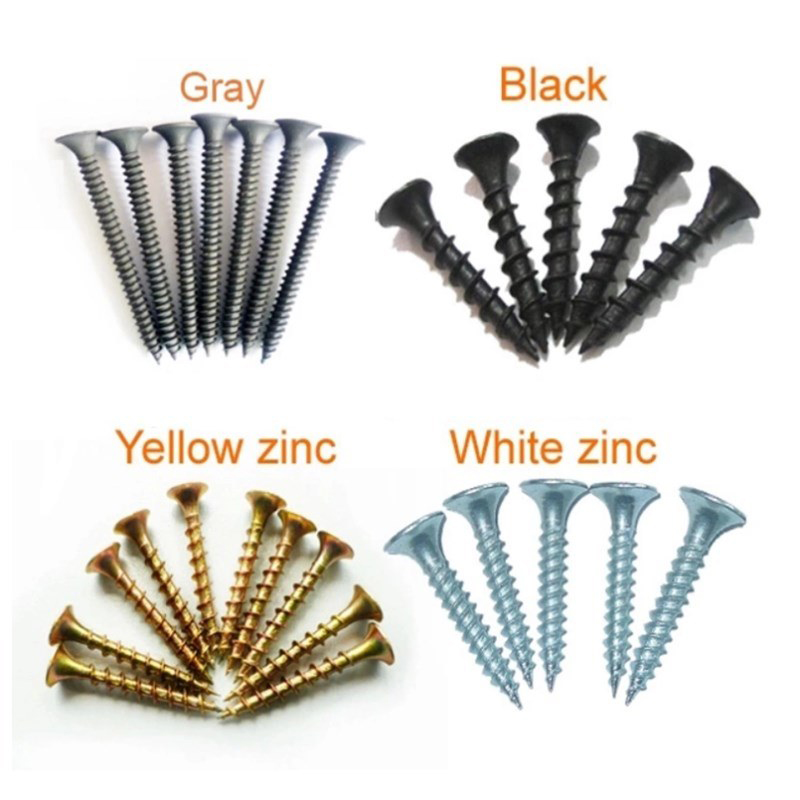

Drywall screws are made of carbon steel, which has increased strength. To increase the service life of hardware, they are covered with an anti-corrosion layer by phosphating (applying a protective film consisting of metal phosphates) or galvanizing (treatment with white or yellow zinc).

Black drywall screws are ideal for further painting, as paintwork materials adhere especially well to phosphated drywall screws.

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for Fixed Competitive Price Short Drywall Screws - Black Phosphated Bugle Head DIN7505 Drywall Screw – Xinruifeng, The product will supply to all over the world, such as: United States, Ukraine, Muscat, The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!