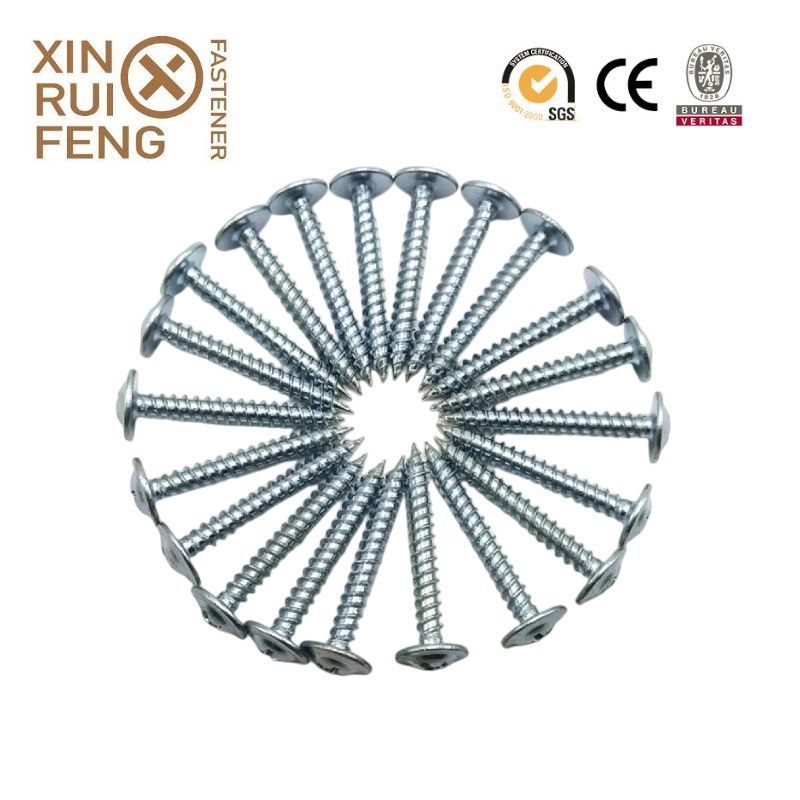

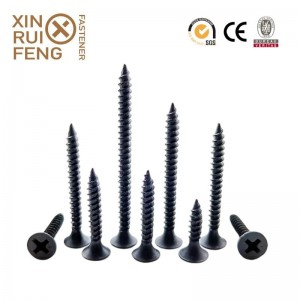

Phillip Drive Zinc Coating Truss Head Self Tapping Screw

"Self tapping screws, Self-tapping screws have a wide range of tip and thread patterns, and are available with almost any possible screw head design. Common features are the screw thread covering the whole length of the screw from tip to head and a pronounced thread hard enough for the intended substrate, often case-hardened via heat treatment process.

We can name the following screws according to head.

Bugle, CSK, Truss, Pan, Hex, Pan framing self tapping screws.

We can name the following screws according to point.

Sharp, type 17 cutting, drill, spoon point self tapping screws."

You can fasten board to wood or metal via driver, you also can fasten metal to metal via driver.

Self tapping screws look like screws, there are different head or points like CSK, bugle, truss, pan, Hex head.

You can fasten board to wood or metal, you also can fasten metal to metal.

You can remove self tapping screws via driver.

yes, coarse thread drywall screw, chipboard screw, timber screws, hex head self tapping screw with sharp point, hex head self tapping screw with spoon point, hex head self tapping screw with drill point.

You can measure self tapping screw via calipers.

Self tapping screws of different sizes are different holding weight.

You can use self tapping screws without a drill via driver to less than 3mm thickness metal.

Self tapping deck screws mainly are used for fastening decking material.